MENU

Ready to Start Machine, laser source, head & control - all connected during transport Compact, Fits in a regular truck, less installation time, less foot print Operator friendly, easy open side covers and for easy maintenance access. Making sure of starting the machine same as factory settings and adjustments. Designed with high precision criteria, rigid body. Power transmission by Rack & Pinion system.

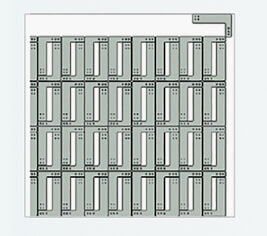

Conventional Nesting

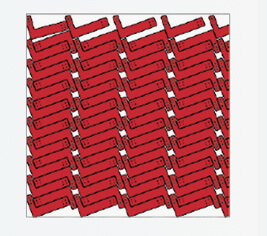

Conventional Nesting Advance Nesting

Advance Nesting| 3015 | 4020 | 6020 | 8020 | ||

|---|---|---|---|---|---|

| X Axis | 3040 | 4030 | 6030 | 8030 | mm |

| Y Axis | 1535 | 2030 | 2030 | 2030 | mm |

| Z Axis | 120 | 120 | 120 | 120 | mm |

| Velocity | 2.5 | 2.5 | 2.5 | 2.5 | g |

| Max. Axes Speed | 150 | 150 | 150 | 150 | meter/minute |

| Syncronized Speed | 210 | 210 | 210 | 210 | meter/minute |

| Positioning Accuracy | +/- 0.05 | +/- 0.05 | +/- 0.05 | +/- 0.05 | mm |

| Repeatibility | +/- 0.03 | +/- 0.03 | +/- 0.03 | +/- 0.03 | mm |

| Machine Weight | 16500 | 22200 | 27750 | 33250 | kg |

| Max. Loading Capacity | 1500 | 2500 | 4000 | 6000 | kg |

| Table Change Time | 24 | 30 | 45 | 60 | sec |

| A | 2600 | 2600 | 2600 | 2600 | mm |

| B | 2300 | 2300 | 2300 | 2300 | mm |

| C | 10000 | 12475 | 16725 | 16725 | mm |

| D | 1150 | 1150 | 1150 | 1150 | mm |

| E | 4150 | 5020 | 5020 | 5020 | mm |

| F | 2370 | 2530 | 2530 | 2530 | mm |

| G | 2030 | 2530 | 2530 | 2530 | mm |

| H | 3450 | 4670 | 6920 | 8730 | mm |

| I | 1240 | 1240 | 1240 | 1240 | mm |

| J | 1200 | 1200 | 1200 | 1200 | mm |

| 1 kW | 2 kW | 3 kW | 4 kW | 5 kW | 6 kW | 8 kW | 10 kW | ||

|---|---|---|---|---|---|---|---|---|---|

| Resonator | YLS-1000 | YLS-2000 | YLS-3000 | YLS-4000 | YLS-5000 | YLS-6000 | YLS-8000 | YLS-10000 | |

| Output Power | 100-1000 | 200-2000 | 300-3000 | 400-4000 | 500-5000 | 600-6000 | 800-8000 | 1000-10000 | w |

| Mild Steel | 8 | 16 | 18 | 20 | 22 | 25 | 30 | 30 | mm |

| Stainless Steel | 4 | 6 | 10 | 12 | 15 | 18 | 20 | 22 | mm |

| Aluminum | 4 | 6 | 8 | 10 | 12 | 15 | 18 | 20 | mm |

| Oxygen Gas Pressure | 13 | 13 | 13 | 13 | 13 | 13 | 13 | 13 | bar |

| Nitrogen Gas Pressure | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | bar |

| Air Gas Pressure | 13 or 25 | 13 or 25 | 13 or 25 | 13 or 25 | 13 or 25 | 13 or 25 | 13 or 25 | 13 or 25 | bar |

| Avg Electricity Consumption | 15 | 20 | 30 | 35 | 45 | 50 | 60 | 70 | kw/h |

© 2020 MVD MAKİNA SANAYİ A.Ş. | All Rights Reserved.