MENU

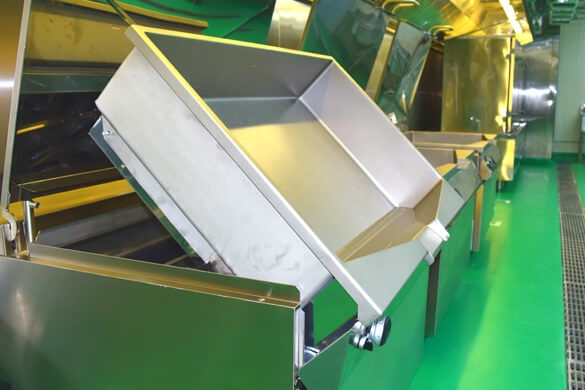

The Industrial Kitchen industry requires manufacturing of machines in four main categories, Kneading/Mixing, Cooking, Serving & Display and Cooling.

During the production of kitchen projects, 430, 304 stainless steel and galvanized sheet materials are most often used. The thickness of the material may range from 0.60 mm to 6 mm. As these are products of high-quality and high value, the error rate during production is required to be extremely low.

In this industry, aesthetics is an integral aspect. In the Industrial Kitchen industry, not only there is no room for error and the specific requirements are very significant, but there is also a decorative and aesthetic concern. We as MVD understand your needs in the Industrial Kitchen Industry and design our machines to fulfill your high standards and provide excellence.

The iBend Press Brake, iShear Guillotine Shears, iPunch Turret Punch and iLaser Fiber Laser machines are used to manufacture, food storage units, tanks used in furnaces, ovens, hoods, coolers and large workbenches and counters for hotels.

In the Industrial Kitchen industry, a significant amount of specified production is necessary, Thus the manufacturing process must accommodate the complex geometry desired in the end products. Technologies such as 3D CNC monitor and CAD/CAM applications make an important contribution to fulfill these demands. Fort the Industrial Kitchen industry both small and medium-sized parts are produced.

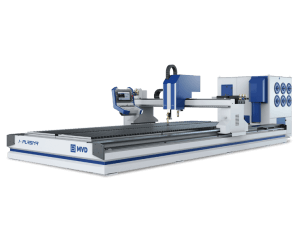

For metal cutting, we suggest iLaser Fiber Laser, iShear Guillotine Shears and iPunch Punch Press machines for the sheet thicknesses that range from 0.60 mm to 6 mm.

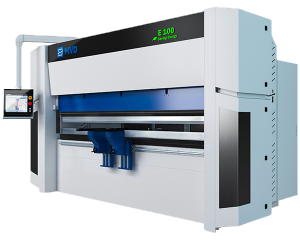

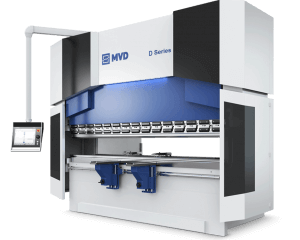

For works that require metal bending, we recommend the bending machines iBend Press Brake and Servo Press Brake for sheets from 0.60 mm to 6 mm and above.

As MVD, we ensure efficient and precise components, goods, tools, and equipment to be produced for the industrial kitchen sector.

We manufacture machines that are capable of

Servo Press Brake as MVD Machines;

In different models and tonnages, we offer our customers the highest quality next-generation bending technology.

Ready to Start Machine, laser source, head & control - all connected during transport Compact, Fits in a regular truck, less installation time, less foot print Operator friendly, easy open side co...

Machines are designed and analyzed with 3-D computer programs, manufactured as welded steel construction, “stress relieved”, precisely machined in moving column CNC machining centers, equi...

Unique construction features combined with great craftmanship Machine body and upper beam’s steel constructions have been designed according to minimum stretch and optimum resistance criteria....

P-Series Plasma machines are used for cutting thick metals, It is a reliable and robust plasma source. Hypertherm cutting head, CNC control unit and power source provides precise and high quality cutt...

MVD Turret Punch presses are produced as a closed type rigid steel constructions in to a robust structure to provide minimum deflection during operation. Complete solutions with effective costs....

Excellent features of CNC Controlled Expanded Metal Machine: Auto Blade gap adjustment, German Made Roll Bearings and Crank Shaft, easy to operate, no waste production, high speed, high precision, var...

© 2020 MVD MAKİNA SANAYİ A.Ş. | All Rights Reserved.