MENU

In the Home Appliance Industry the most commonly manufactured products are, refrigerators, ovens, washing machines, the dishwasher doors and panels, as well as kitchen stoves and hoods. High output volume and productivity are the key factors of this industry. Moreover, the Home Appliances Industry necessitates a variety of designs and personalized products to keep up with differing demands. Thus, the Home Appliances Industry needs adaptable and versatile machines in the manufacturing process. The machines used in the manufacturing process of the Home Appliances Industry must be able to quickly switch between different productions, and allow flexible production.

In the Home Appliances Industry small and medium-sized pieces are used most often. In this industry, mild steel, galvanized steel, and stainless steel are the most frequently used materials, with the material thickness varying between 0.60 mm and 2 mm. As aesthetics is a big part of the industry, the materials used in the manufacturing process can be pre-painted or stainless steel.

Due to the important aesthetic value of the end products, manufacturing operations need to be carried out in precision, and without leaving unwanted any marks on the material. The manufacturing process of the Home Appliances Industry requires precision cutting lasers, bending molds and blades.

As, MVD we produce machines that give flawless results efficiently, thanks to our engineers' superior expertise and skills.

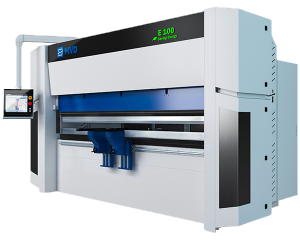

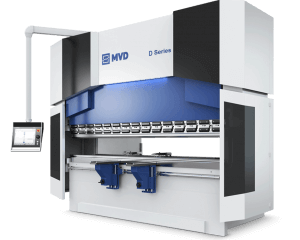

Commonly used MVD machines in this sector are iBend Press Brake, iLaser Fiber Laser, iPunch Punch Press and iShear Guillotine Shear.

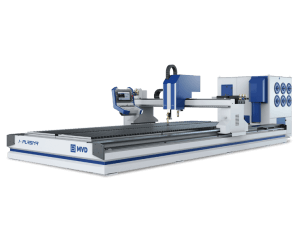

For manufacturing processes that include cutting steel, we recommend our following products: iLaser Fiber Laser, iShear Guillotine Shears and iPunch Turret Punch machines for sheet thicknesses that vary from 0,60 mm to 2 mm.

For the manufacturing processes that include bending steel, we suggest our machines iBend Press Brake and Servo Press Brake for sheets that vary from 0,60 mm to 2 mm.

As MVD, we enable your Home Appliance manufacturing to be accurate, error-free and aesthetic, with the use of our specialized molds that can be customized for your needs.

We manufacture machines that

Servo Press Brake as MVD Machines;

In different models and tonnages, we offer our customers the highest quality next-generation bending technology.

Ready to Start Machine, laser source, head & control - all connected during transport Compact, Fits in a regular truck, less installation time, less foot print Operator friendly, easy open side co...

Machines are designed and analyzed with 3-D computer programs, manufactured as welded steel construction, “stress relieved”, precisely machined in moving column CNC machining centers, equi...

Unique construction features combined with great craftmanship Machine body and upper beam’s steel constructions have been designed according to minimum stretch and optimum resistance criteria....

P-Series Plasma machines are used for cutting thick metals, It is a reliable and robust plasma source. Hypertherm cutting head, CNC control unit and power source provides precise and high quality cutt...

MVD Turret Punch presses are produced as a closed type rigid steel constructions in to a robust structure to provide minimum deflection during operation. Complete solutions with effective costs....

Excellent features of CNC Controlled Expanded Metal Machine: Auto Blade gap adjustment, German Made Roll Bearings and Crank Shaft, easy to operate, no waste production, high speed, high precision, var...

© 2020 MVD MAKİNA SANAYİ A.Ş. | All Rights Reserved.