MENU

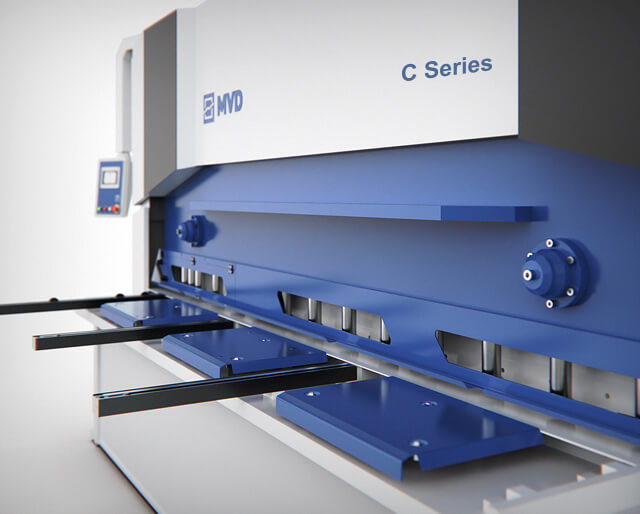

C Series Hydraulic Variable Rake Angle Shears automatic cutting angle calculating, provides high cutting quality in the widest range of materials type and sheet thickness. Automatically calculates and apply; cutting angle, blade gap adjustment, stroke of the cutting length, back gauge positioning according to material type and thickness with CNC controller and servo hydraulic valve.

| Machine Type | Cutting Capacity | Cutting Length | Cutting Angle | Hold Down Cylinders | Cutting Speed / Fast Mode | Distance Between Columns | Table Height | Table Width | Throat Depth | Backguage Travel – X Axis | Machine Dimensions | Oil Tank Capacity | Motor Power | Weight | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 450 N/mm² | 700 N/mm² | A | Min-Max | Qty | hpm | B | C | D | E | mm | Length x Width x Height (F x G x H) |

lt | Kw | Tons | |||

| mm | mm | mm | Degree (°) | mm | mm | mm | mm | F | G | H | |||||||

| C06/3100 | 6 | 4 | 3100 | 0,5-2 | 14 | 10/15 | 3500 | 835 | 520 | 250 | 1000 | 4830 | 2995 | 1975 | 200 | 10 | 6,7 |

| C08/3100 | 8 | 5 | 3100 | 0,5-2,7 | 14 | 10/15 | 3500 | 900 | 615 | 250 | 1000 | 4830 | 3140 | 2150 | 275 | 15 | 7,5 |

| C10/3100 | 10 | 6 | 3100 | 0,5-3 | 14 | 7/13 | 3600 | 880 | 620 | 250 | 1000 | 4950 | 3415 | 2415 | 295 | 22 | 10,5 |

| C13/3100 | 13 | 8 | 3100 | 0,5-3 | 14 | 7/13 | 3600 | 900 | 620 | 250 | 1000 | 4970 | 3670 | 2505 | 295 | 22 | 12,8 |

| C16/3100 | 16 | 10 | 3100 | 0,5-3 | 17 | 6/12 | 3670 | 995 | 705 | 250 | 1000 | 5060 | 3810 | 2680 | 340 | 30 | 16 |

| C20/3100 | 20 | 13 | 3100 | 0,5-3 | 17 | 5/10 | 3705 | 995 | 720 | 250 | 1000 | 5115 | 3800 | 2680 | 510 | 37 | 22 |

| C25/3100 | 25 | 17 | 3100 | 0,5-3 | 17 | 4/8 | 3760 | 995 | 720 | 250 | 1000 | 5150 | 3850 | 2730 | 510 | 45 | 24 |

| C06/4000 | 6 | 4 | 4000 | 0,5-2 | 17 | 10/14 | 4460 | 860 | 650 | 250 | 1000 | 5790 | 3165 | 2210 | 200 | 10 | 10,7 |

| C08/4000 | 8 | 5 | 4000 | 0,5-2,7 | 17 | 9/13 | 4460 | 880 | 650 | 250 | 1000 | 5800 | 3400 | 2350 | 200 | 15 | 14 |

| C10/4000 | 10 | 6 | 4000 | 0,5-3 | 18 | 6/12 | 4460 | 880 | 650 | 250 | 1000 | 5790 | 3650 | 2580 | 300 | 22 | 16 |

| C13/4000 | 13 | 8 | 4000 | 0,5-3 | 18 | 6/12 | 4460 | 900 | 700 | 250 | 1000 | 5860 | 3830 | 2675 | 300 | 22 | 18 |

| C16/4000 | 16 | 10 | 4000 | 0,5-3 | 18 | 6/12 | 4580 | 1010 | 700 | 250 | 1000 | 5980 | 3750 | 2825 | 390 | 30 | 21,5 |

| C20/4000 | 20 | 13 | 4000 | 0,5-3 | 18 | 5/10 | 4590 | 1025 | 720 | 250 | 1000 | 6000 | 3775 | 2830 | 510 | 37 | 27 |

| C25/4000 | 25 | 17 | 4000 | 0,5-3 | 18 | 4/8 | 4600 | 1025 | 735 | 250 | 1000 | 6000 | 3875 | 2930 | 510 | 45 | 30 |

| C06/6100 | 6 | 4 | 6100 | 0,5-3 | 26 | 9/13 | 6490 | 1050 | 735 | 250 | 1000 | 7900 | 3585 | 2885 | 300 | 11 | 22 |

| C08/6100 | 8 | 5 | 6100 | 0,5-3 | 26 | 8/12 | 6500 | 1100 | 735 | 250 | 1000 | 7900 | 3685 | 2985 | 300 | 15 | 24 |

| C10/6100 | 10 | 6 | 6100 | 0,5-3 | 26 | 5/12 | 6500 | 1135 | 735 | 250 | 1000 | 7960 | 3785 | 3085 | 300 | 22 | 27,8 |

| C13/6100 | 13 | 8 | 6100 | 0,5-3 | 26 | 5/12 | 6500 | 1255 | 845 | 250 | 1000 | 7890 | 3910 | 3270 | 300 | 22 | 36,5 |

| C16/6100 | 16 | 10 | 6100 | 0,5-3 | 26 | 5/9 | 6650 | 1270 | 920 | 250 | 1000 | 8060 | 3880 | 3290 | 430 | 30 | 40 |

| C20/6100 | 20 | 13 | 6100 | 0,5-3 | 26 | 5/7 | 6650 | 1285 | 1100 | 250 | 1000 | 8060 | 4170 | 3305 | 535 | 37 | 50 |

| C25/6100 | 25 | 17 | 6100 | 0,5-3 | 26 | 4/6 | 6670 | 1350 | 1100 | 250 | 1000 | 8150 | 4170 | 3450 | 600 | 45 | 58 |

© 2020 MVD MAKİNA SANAYİ A.Ş. | All Rights Reserved.