MENU

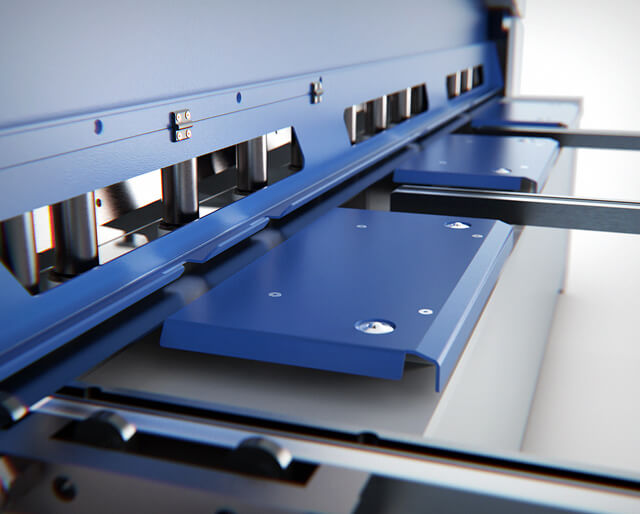

Increased productivity with double speed concept.50% more cuts/minute with half of the original cutting capacity. Shears cutting thickness from 6 mm – up to 25 mm, cutting length from 2 meter – up to 6 meter. Provides high cutting quality with low cutting angle design machine concepts. Unique construction feature has a fixed angle of cut.

| Machine Type | Cutting Capacity | Cutting Length | Cutting Angle | Hold Down Cylinders | Cutting Speed / Fast Mode | Distance Between Columns | Table Height | Table Width | Throat Depth | Backguage Travel – X Axis | Machine Dimensions | Oil Tank Capacity | Motor Power | Weight | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 450 N/mm² | 700 N/mm² | A | Degree (°) | Qty | hpm | B | C | D | E | mm | Length x Width x Height (F x G x H) |

lt | Kw | Tons | |||

| mm | mm | mm | mm | mm | mm | mm | F | G | H | ||||||||

| B06/2100 | 6 | 4 | 2100 | 1,5 | 10 | 21/30 | 2330 | 850 | 500 | 250 | 1000 | 3630 | 2965 | 1990 | 160 | 10 | 4,3 |

| B06/2600 | 6 | 4 | 2600 | 1,5 | 11 | 20/26 | 2830 | 850 | 500 | 250 | 1000 | 4130 | 2965 | 1990 | 160 | 10 | 5,5 |

| B06/3100 | 6 | 4 | 3100 | 1,5 | 14 | 18/23 | 3330 | 865 | 500 | 250 | 1000 | 4630 | 2965 | 1990 | 160 | 10 | 6 |

| B08/3100 | 8 | 5 | 3100 | 1,9 | 14 | 13/18 | 3340 | 865 | 580 | 250 | 1000 | 4660 | 3470 | 2065 | 265 | 15 | 8 |

| B10/3100 | 10 | 6 | 3100 | 2 | 14 | 13/18 | 3340 | 880 | 600 | 250 | 1000 | 4675 | 3520 | 2140 | 265 | 22 | 9,6 |

| B13/3100 | 13 | 8 | 3100 | 2,1 | 14 | 9/14 | 3340 | 880 | 620 | 250 | 1000 | 4680 | 3585 | 2300 | 265 | 22 | 11,5 |

| B16/3100 | 16 | 10 | 3100 | 2,25 | 17 | 7/10 | 3410 | 880 | 585 | 200 | 1000 | 4780 | 3750 | 2300 | 495 | 30 | 15,8 |

| B20/3100 | 20 | 13 | 3100 | 2,75 | 17 | 6/9 | 3410 | 925 | 605 | 150 | 1000 | 4790 | 3850 | 2540 | 495 | 37 | 19 |

| B25/3100 | 25 | 17 | 3100 | 2,75 | 17 | 5/8 | 3460 | 1000 | 630 | 250 | 1000 | 4930 | 3850 | 2980 | 495 | 55 | 27 |

| B06/4000 | 6 | 4 | 4000 | 1,5 | 18 | 13/20 | 4230 | 870 | 600 | 250 | 1000 | 5550 | 3340 | 2165 | 250 | 10 | 10,8 |

| B08/4000 | 8 | 5 | 4000 | 1,5 | 18 | 13/20 | 4240 | 870 | 630 | 250 | 1000 | 5570 | 3625 | 2190 | 265 | 22 | 13,2 |

| B10/4000 | 10 | 6 | 4000 | 1,5 | 17 | 11/17 | 4240 | 890 | 635 | 250 | 1000 | 5580 | 3725 | 2290 | 265 | 22 | 16,2 |

| B13/4000 | 13 | 8 | 4000 | 1,8 | 18 | 9/15 | 4310 | 930 | 660 | 250 | 1000 | 5665 | 3785 | 2380 | 350 | 22 | 18,5 |

| B16/4000 | 16 | 10 | 4000 | 2,15 | 18 | 5/16 | 4310 | 960 | 625 | 250 | 1000 | 5680 | 3840 | 2575 | 490 | 30 | 22 |

| B20/4000 | 20 | 13 | 4000 | 2,03 | 18 | 4/15 | 4390 | 960 | 710 | 250 | 1000 | 5780 | 3930 | 2800 | 490 | 45 | 26,3 |

| B06/6150 | 6 | 4 | 6150 | 1 | 26 | 4/10 | 6440 | 950 | 750 | 250 | 1000 | 7770 | 3655 | 2300 | 345 | 22 | 26,5 |

| B08/6150 | 8 | 5 | 6150 | 1,2 | 26 | 4/9 | 6450 | 1000 | 810 | 250 | 1000 | 7780 | 3700 | 2400 | 345 | 22 | 28,5 |

| B10/6150 | 10 | 6 | 6150 | 1,2 | 26 | 3/7 | 6460 | 1000 | 810 | 250 | 1000 | 7780 | 3750 | 2500 | 345 | 22 | 30,5 |

© 2020 MVD MAKİNA SANAYİ A.Ş. | All Rights Reserved.